The vending machine from HAHN+KOLB stores tools, aids or consumables that are important to your production processes and enables employees to access them easily. The dispenser monitors and logs each removal. If there is only a small number of a certain item left in the HK-MAT, the system will automatically reorder the item to ensure that vital work equipment is available whenever it's needed.

Your benefits:

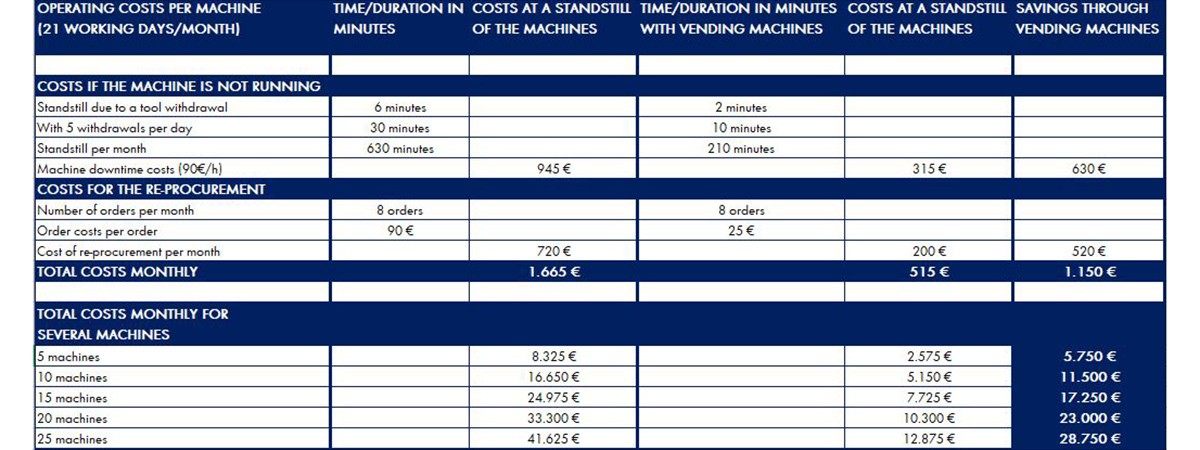

The potential for savings through the use of an output system in machining production

Many different types of costs are incurred in everyday work: Labor costs due to search and removal times, costs due to machine downtime, costs for the maintenance of a centrally managed tool vending system as well as the costs for the replacement of used tools.

For a detailed process cost calculation - individually tailored to your needs - we will be pleased to be at your disposal. We can calculate other factors for you, from demand recognition to purchase requisition to electronic invoice receipt.

Our simplified overview gives you a quick overview of how a manual goods issue compares to a digital issue system.

We fully respect your privacy. In order to make you feel secure and confident when visiting our website, we observe all current legislation when collecting, processing and using personal details.

For the gathering of data, cookies are used. No personal data will be stored. The cookies that we use are described in our Data Protection Statement.